Sorting

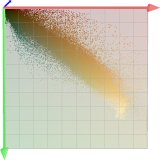

equipment of the type OptoSort® is learning. With the help of

the

system function „training “by the user after

identical

color characteristics selected objects are driven over the

sorting

equipment and registered as color class. In addition it is enough to

drive some good material in the simplest case first somewhat over the

sorting equipment, followed by a small quantity of bad material.

Already finest differences in color can be recognized by the sensitive

camera system and the training procedure. Up to eight different and

freely parametrable color classes can be trained and weighted. By the

help of a probability distribution by Bayes outliers in the trained

material are eleminated in the assigned decision table.

By

morphologic functions the material admission can be improved

besides, disturbing particles and noise for

example will

removed or the weighting of hotspots strengthened.

The sort decision whether an object is good or bad is meet by the

system due processing a programable decision chain. Decisions are

possible on the basis of the color surfaces, color composition

and

geometrical characteristics. Surface thresholds for the color classes

are typical, whereby each class can still be linked logically if

necessary for recognize complex color compositions, for example with

quartz.

Depending upon installation type only a few

milliseconds pass between the detection of an object by the camera

system and the entrance into the range of the ejector bar, this offense

ensure a precise removing with little product lost. As a result of a

material-specific selection of the valves, inserted with small distance

to the flight path of the material and the accurate object recognition

and control the compressed air consuption is a very small.